Frame Downloads and Intellectual Property

One of our main goals at AeroBat is to bring frame manufacturing into the hands of the hobbyist. When you crash your drone, we want your only concern to be how much filament you need to print another.

At the same time, our frame designs are our primary intellectual property. Once a file is out in the community, it can’t really be taken back.

Because of that, we’ve decided to offer a selection of our designs as downloadable files while keeping some premium models exclusive to our shop. This allows us to support the DIY side of FPV while also protecting the work that makes AeroBat possible.

If you want to fly AeroBat, we encourage you to purchase the file directly from us. Print it, crash it, reprint it as many times as you’d like.

No Printer? No Problem.

Printing can be difficult, and engineering filaments can be frustrating to work with.

If you like our designs but don’t want to deal with the hassle of printing, check out our shop where we offer frame kits manufactured under ideal conditions. This is also the best way to support AeroBat and help keep new designs coming.

Why Some Frames Aren’t Downloadable

Some of our premium models will not be available for download at release, although that may change in the future.

Designing and testing new frames takes time, materials, and constant iteration. To keep AeroBat growing and fund future development, certain premium frames will only be available through our shop.

Every purchase genuinely means the world to us and directly supports our ability to keep designing for this community!

3D Printing AeroBat Frames

Picking The Right Material

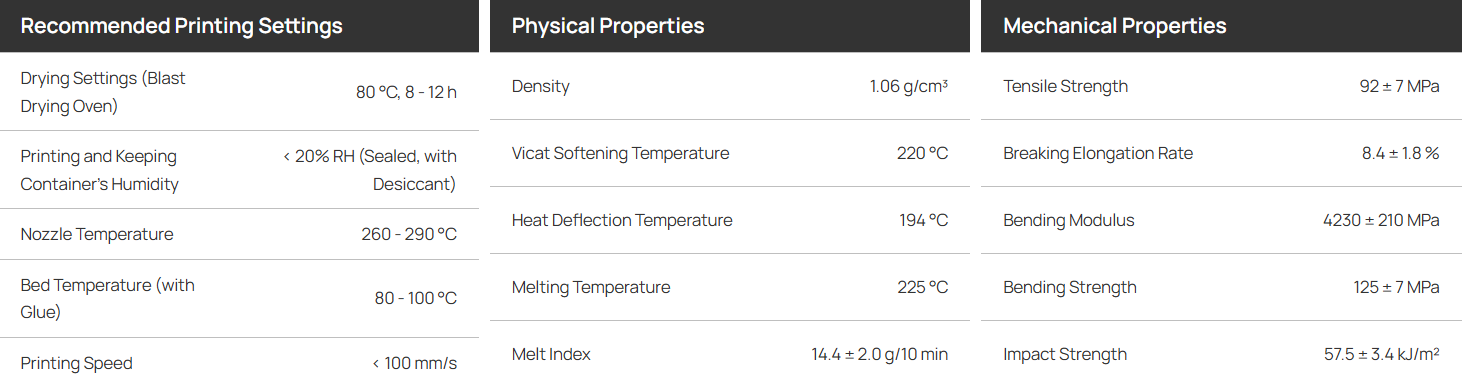

RECOMMENDED MATERIAL #1: PAHT-CF (Best Overall for Freestyle)

PAHT-CF is the ideal filament for freestyle FPV frames because it offers the best balance of stiffness, toughness, and crash survivability. After months of iteration and real-world testing, it has proven to be the most reliable choice for pilots who want a frame that can take repeated impacts without cracking or failing.

Compared to most carbon-filled materials, PAHT-CF maintains excellent rigidity while still having enough flexibility to absorb hard hits. This makes it perfect for freestyle flying, where durability matters just as much as flight feel.

Why we recommend PAHT-CF:

Excellent impact resistance (ideal for crashes)

Strong rigidity for stable flight performance

High heat resistance and long-term durability

Best all-around material for freestyle drone frames

(This is The Pick for 95% of Pilots)

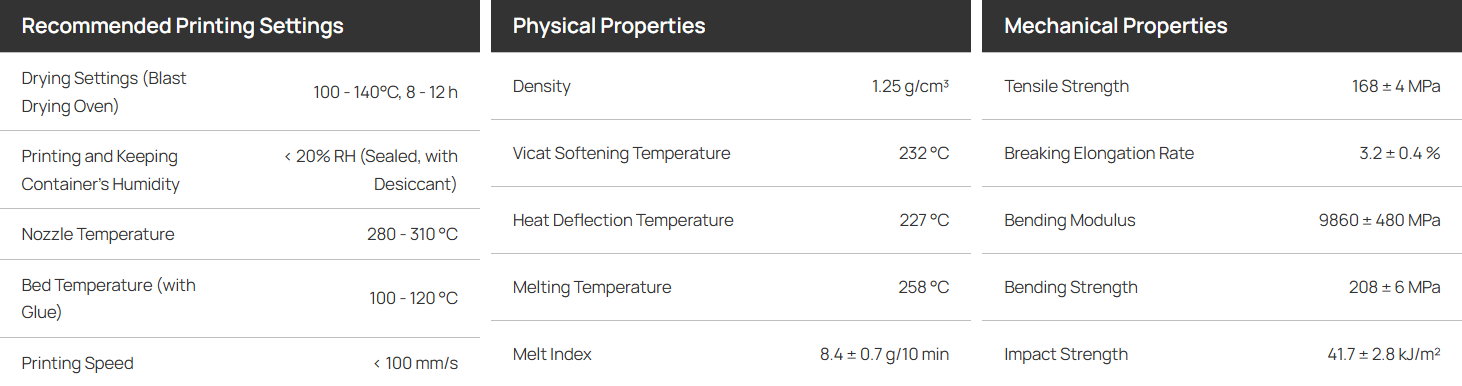

RECOMMENDED MATERIAL #2: PPA-CF (Max Stiffness / Flight Feel)

For pilots who prioritize the sharpest possible flight performance, PPA-CF is an excellent alternative. It is noticeably stiffer than PAHT-CF, which can result in a more locked-in feel, better vibration control, and cleaner response at high RPM.

The tradeoff is that PPA-CF is typically less impact resistant, meaning it may crack or fracture more easily during heavy crashes. This makes it better suited for performance-focused builds where flight feel is the priority and crash durability is less critical.

Why choose PPA-CF:

Extremely stiff for maximum control

Cleaner flight characteristics and reduced flex

Excellent vibration performance

Best choice for performance-first builds

Tradeoff:

More brittle in crashes (higher chance of cracking compared to PAHT-CF)

The material property data shown above is sourced from Bambu Lab’s published specifications and is displayed here for informational purposes only. All referenced trademarks and content remain the property of their respective owners.

Print Parameters

When you purchase a frame download from AeroBat, you’ll receive the raw STL file along with an optimized print profile designed to deliver the best balance of strength, stiffness, and crash performance.

These parameters were developed through extensive real-world testing and are the settings we personally recommend for achieving the intended flight characteristics.

If your goal is to reduce weight, we recommend starting by lowering top and bottom layers. Wall count is the most important strength parameter for drone frames, while infill primarily influences vibration damping and overall feel. For infill, we recommend gyroid for the best balance of strength and resonance control.

Printing Tips

DRY YOUR FILAMENT. Your filament must be bone-dry before printing. Nylon absorbs moisture quickly (sometimes within hours), which leads to weak layer adhesion and ugly prints.

USE A BRIM. A brim solves most minor warping issues. We recommend a 10mm brim for consistent bed adhesion.

THICK GLUE LAYER. Apply a healthy layer of glue. Aim for a sticky 2–3 layer coat (avoid letting liquid glue pool up). Engineering filaments are especially prone to warping without proper adhesion.

STABLE CHAMBER TEMPERATURE. Keep your enclosure temperature stable throughout the print. Temperature changes can create layer line anomalies and reduce consistency. Refer to the charts above for recommended temperatures.

PRIORITIZE WALLS OVER INFILL. Wall count is the most important strength parameter for drone frames. If you want durability, increase wall count before increasing infill.

USE GYROID INFILL. Infill is mainly useful for vibration control and stiffness tuning. We recommend gyroid for the best balance of strength and resonance performance.

SLOW DOWN OUTER WALLS. Printing outer walls too fast can reduce surface quality and weaken layer bonding. Slower outer walls produce cleaner, stronger parts.

PRINT HOT (WITHIN THE RECOMMENDED RANGE). Higher nozzle temperatures generally improve nylon layer adhesion. If your prints feel brittle or weak, increasing nozzle temperature slightly is often the first fix.

MINIMIZE PART COOLING. Excessive fan cooling can weaken nylon prints. Keep part cooling low unless bridging requires it.

USE A HARDENED OR TUNGSTEN NOZZLE. Carbon fiber filaments are abrasive and will destroy brass nozzles quickly. Hardened steel is the minimum recommended, and tungsten is ideal for long-term use.

We’ve printed and tested hundreds of frames across a variety of printers and materials. Below are the tips that have made the biggest difference in print quality and reliability.